| |

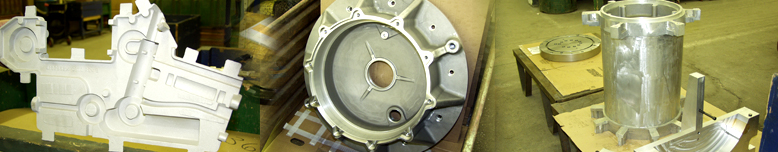

Hebert Foundry & Machine, Inc. has extensive experience in the aluminum sand casting foundry industry. The process of pouring molten aluminum into a sand mold continues to be a cost effective process, supplying parts to a variety of industries. Because of its positive features, aluminum remains the metal of choice across the automotive industry. Notwithstanding the automotive industry, aluminum sand casting continues to be used in other areas of the transportation industry including in aircraft and marine applications.

Other industries served include machine tool fabrication, communication, medical and laboratory testing equipment, and food preparation machinery. Aluminum sand casting is the right choice for products that require hollow cavities and complex, unique arrangements of voids, shapes and ribs. Aluminum sand castings can be supplied in sizes from fractions of an ounce to 400 pounds; from 3/8 inch to 120 inches in width or length; and from one piece to tens of thousands of units.

Aluminum castings are typically 0.10 pounds per cubic inch vs. 0.25 for ZA-12, 0.28 for iron, 0.29 for steel, 0.30/0.31 for brass/bronze, 0.33 for stainless steel. For high quantity applications, HFM can supply and machine permanent mold aluminum sand castings for the lowest price and highest dimensional quality with short turnaround times.

HFM provides aluminum sand casting in the following alloys:

• 355 and 356 aluminum alloys which are heat treated to T6 and T7 conditions

• 319 aluminum alloy which is typically used without heat treatment (F)

• 443 aluminum alloy

• 535 aluminum-magnesium alloy for elongation and corrosion resistance

• 713 aluminum alloy for physical strength of 356 without the heat treatment

• ZA-12 zinc-aluminum for replacement of grey iron castings in many applications

|

|